Date: 12-2-2016

ARBS Refrigeration project excellence awards 2016 ( runner up )

Project excellence awards submission

Project name Sylvan Australia ammonia glycol chiller

Entrant Strathbrook Industrial Services & Danfoss

Location Sylvan Australia

189The Northern rd

Londonderry NSW 2753

Entrant contact Ian Wilson

Site contact Keivan Bezanehtak

Project type glycol cooling with heat recovery

System capacity 105kw @ -2.5sst and +32sct R717

Nature of business Mushroom spore production

Design brief

Sylvan Australian is Australian’s largest producer of Mushroom spore, and services the National Mushroom growing industry. Their existing glycol temperature control system was approaching 20 years of age and was costing increasingly larger amounts of capital to keep it in service.

The glycol is heated to 120 deg C by a gas fired boiler and is used to sterilize the raw materials for the growing medium (wetted grain products such as wheat) prior to the introduction of the mushroom spore. Once the grain has reached its sterilization temperature, the glycol has to be cooled to 6 deg C so the growing medium can be cooled prior to the introduction of the spore and subsequent product bagging. The glycol is pumped around a jacketed vat which rotates so that the grain inside the vat can achieve an even temperature throughout the process.

The existing system consisted of an air cooled heat exchanger to reduce the temperature of the glycol from 120 deg C to 30 deg C and then an R22 air cooled chiller to further reduce the temperature to 6 deg C.

The client required a new system to replace the aging equipment, but also required a reduction in energy consumption and a reduction in the environmental foot print of the site.

System description

The warm product is heated by glycol which is heated in a steam to glycol heat exchanger located inside the factory. The glycol is required to be heated by a boiler to 120deg C and then maintained at this temperature until the product in a rotating storage vat known as the Blender . When the product in the blender reached the required temperature the glycol is then cooled so the product can be further processed.

As the glycol is at 120 deg C at the start of the process, a water cooled braised plate heat exchanger was chosen as the most appropriate heat transfer solution.

As cooling towers require constant maintenance and have a tendency to wash contaminants into the water, a sealed closed loop system was selected. The closed loop solution removes the need to clean out the heat exchanger and also removes the need to do tower washes water treatment and chemical dosing for legionnaires disease.

A Guntner dry cooler with eight EC fans provides the basic heat rejection capacity, and a water pump circulates water between the plate heat exchanger and the dry cooler so the heat can be transferred from the hot glycol to the ambient air.

Once the glycol has been reduced to 30deg C a pair of existing motorized valves divert the glycol flow from the plate heat exchanger to a 2000Litre buffer tank which is held at 6 deg C by the chiller.

The warm glycol mixes with the cold glycol to further reduce the temperature and an instant cooling load is created for the glycol chiller that is located beside the buffer tank.

When the glycol diverting valves change position the primary water pump is shut down and a secondary pump circulated the cooling water between the dry cooler and the chiller’s water cooled condenser, so that the dry cooler then becomes the heat rejection heat exchanger for the ammonia chiller

The ammonia chiller also has a heat recovery system which warms water used to supply the boiler, and the water mixed with the grain to achieve the right moisture content.

The nickel braised plate heat exchanger absorbs heat from the ammonia compressors discharge line, by de superheating the ammonia discharger vapor and warming the water. The amount of heat that can be recovered starts off very high, but reduces as the water heats up in the warm water pipe work.

Ammonia Chiller description

Executive summary

The ammonia chiller was designed and built by Strathbrook Industrial services, and is designed to produce chiller water/Glycol from the evaporator and hot water from the heat recovery heat exchanger and is a critical charge system.

The chiller is self-contained and has an on board control panel with dedicated control and power system.

The cooling capacity is 105kw at -2.5deg C saturated suction temperature, and the water heater has a variable heating capacity which increases in capacity as the water temperature entering the heat recovery heat exchanger falls.

The chiller is water cooled and is feed with water from an air cooled closed loop water cooler or dry cooler.

The refrigeration circuit has a single Direct Expansion (DX) Ammonia plate heat exchanger evaporator with a single Bitzer six cylinder reciprocating piston compressor which circulates 4.9kg of anhydrous ammonia.

The chiller is equipped with a safety system which includes compressor, glycol and water flow safety devices and ammonia leakage detection.

The machine is supplied with removable panels so the system can be located in the weather.

Detailed description

The chiller is a 105kw capacity at the current operating parameter.

The Bitzer W6FA-K direct coupled compressor has a self-aliening coupling housing, and direct drive coupling and is connected to a 1450rpm 4 pole 37 kw foot flange motor.

The compressor has a variable speed drive with an operating range of 25Hz to 50 Hz but could be increased to 60 Hz if required. The compressor also has a single unloading cylinder head which is capable of reducing the compressors capacity by 33%. The unloading head is controlled by a single Danfoss auto reset pressure control and is intended to allow the compressor to operate at minimum speed in the unloaded state so that the compressor doesn’t short cycle during low load conditions.

The compressor has a positive displacement oil pump and oil pressure safety control (Danfoss MP55A) to monitor the oil pressure during operation. An oil heater supplied from the start relay warms the oil when the compressor is not operating. An oil drain valve (“valve C”) is fitted to the bottom of the compressor sump for service access.

The oil level is controlled by a Traxon oil watch which is bolted to the sight glass position in the side of the crankcase. The oil watch has three lights that show the current operating state of the oil system.

Green = correct oil level

Orange = oil filling from oil reservoir

Red = low oil level..

The Traxon device is wired to the oil fill solenoid valve (“valve x’) via a relay, and opens the oil solenoid valve when the light is in the orange state. The Traxon devise indicates red if a low oil level is current, but is not connected to the compressor safety system.

Only the Danfoss MP55A can stop the compressor in the event of low oil level or low oil pressure.

The compressor also has a discharge “valve A” and suction service valve “valve B” which are labelled with trefelight labels . An oil system valve “valve C” is located in the suction bell housing.

The discharge line is piped in 1-1/2” steel pipe and feeds hot discharge vapor to the oil separator/reservoir vessel. The oil separator removed most of the oil from the discharge vapor and stores it in the reservoir below. Two sight glasses show the oil level in the reservoir.

The bottom of the reservoir has a steel tube feeding high pressure oil to the oil solenoid valve “ valve x “. The oil passes through an oil filter, oil solenoid valve and isolation valve before returning to the compressor.

The refrigerant outlet of the oil separator has a stop check valve that prevents back flow when the compressor is at a standstill. (green cap ) “valve D “. The hot discharge gas then enters the heat recovery heat exchanger. Water from the batching water storage tank or the boiler feed tank is pumped into the heat exchanger and the heat in the ammonia is used to heat the water. When the water is cold the heat exchanger will act as a condenser and the heat recovery will be significant. As the water heats, less heat will be absorbed from the refrigerant and the available heat recovery will reduce. When the water temperature in the heating system rises above the condensing temperature the ammonia will no longer condense in the heat recovery heat exchanger and only vapor will pass through the lower exit port into the condenser.

The condenser is located below and beside the heat recovery heat exchanger and is feed with cool water from the closed loop water cooler (dry cooler). The condenser will condense the ammonia into a liquid and gravity will feed it out the bottom of the heat exchanger and through the liquid drier shell isolation valve “valve F “. The liquid then enters the drier shell which also acts as a liquid receiver, and is fitted with three bullseye sight glasses to allow the liquid level in the drier shell to be known.

The liquid then passes through the drier shell outlet isolation valve “valve H “ into the liquid line.

A drier service valve “valve G” is located on the top of the drier shell. The liquid charging valve “valve I “ is located in the liquid line and is a ½” valve.

The liquid line delivers liquid refrigerant to the liquid expansion valve station. The valve station is a Danfoss ICM valve assemble and has a stop valve, a liquid strainer, a liquid line solenoid valve with manual jacking stem, a electronic expansion motor valve with an Icad motor assembly, and an outlet isolation valve, plus 3/8” service valve and liquid sight glass is also included.

The motorized valve controls the supply of liquid refrigerant into the evaporator and is controlled by a Danfoss EKC315A valve controller. The controller will maintain the flow of liquid so that 6k of superheat is maintained (4 to 10k operating limits).

The evaporator pressure is monitored by a pressure transducer located in the suction line after the evaporator and the leaving gas temperature is monitored by a PT1000 sensor in a pocket in the suction line.

The suction line is fitted with a ICS -3 control valve which has a CVP pressure regulator to control the evaporator pressure during the oil recovery cycle, and an EVM solenoid valve to drive the valve fully open during normal operation ( energizer to open fully, de-energizer to back up the pressure in the evaporator).

The back of the evaporator plate heat (PHX) exchanger has an oil feed line fitted to it so that oil and refrigerant can be drawn out of the PHX. When an oil recovery cycle is started the oil recovery solenoid valves opens and allows a mixture of liquid refrigerant and oil from the bottom of the heat exchanger to pass through a filter housing and then a sight glass (under the VSD) before being injected into the suction line.

The oil recovery solenoid valve is energized the ICS EVM solenoid valve is de-energized which increases the evaporator pressure by 80kpa which is enough to push the oil /refrigerant mixture into the suction line so it can return to the compressor.

The oil recovery cycle runs for 5 seconds every 20min and is controlled by a timer in the electrical panel.

The suction line has a suction accumulator to catch any liquid overfeed and return it in a controlled way.

The system had service access valves in the discharge line on either side of the separator, the suction line, the liquid line, the liquid flow control valve station, the compressor sump and it also has removable service plugs in the suction and discharge service valves.

The system pressure can be monitored on two dial pressure gauges located in the side of the machine and are connected to the pipe work in the same location as the control system pressure transducers and the manual safety pressure controls. Each of these two controls assemblies has an isolation valve for service.

The system is fitted with two pressure relief valves. The Suction line has a 1600kpa valve and the discharge has a 2500kpa valve.

The system has an ammonia gas detector inside the machine which will detect a leak of refrigerant.

The control system has a Danfoss pack controller to control the operation of the ammonia system, and has suction and discharge pressure transducers, plus condenser water temp and product water temp sensors.

The controller displays the current operating pressures for suction and discharge plus the % of load.

A Danfoss Variable speed drive (VSD) receives a control signal from the pack controller which sets the current compressor speed in a range between 25hz and 50 Hz.

The controller has a set point of 270 kpa (-4 deg C ) and has a dead band of 40kpa either side of the set point.

If the suction pressure falls below the set point -40kpa the compressor will slow down. If the suction pressure rises above set point +40kpa the compressor will speed up. Once the compressor is at maximum or minimum speed the compressor will remain at that point until the operating conditions either return within the normal range or go outside the safety cut out set points. If the high or low pressure safety is exceeded the compressor will stop.

The low pressure safety set point is 180kpa.

The high pressure safety set point is 2000kpa

Manual safety pressure controls are also provided and are set just outside the electronic system set points.

The unloader control is a manual pressure control and it will unload the compressor below 200kpa and will reload the compressor at 270kpa

The system has condenser water flow control and chilled glycol flow control which will both stop the compressor if there is no flow.

An anti freeze safety control will stop the system if it detects glycol below -10 deg C

The condenser water pump has a 5 min run on timer that will keep the pump running for 5 min after the system cancels the run call for the pump. This will prevent the system stopping on no flow before the compressor control system can shut the system down.

The control panel has a system on and a compressor run switch plus a thermistor reset switch on the front panel. An emergency stop button is also provided.

A Perspex cover protects the control panel from weather, and can be opened by undoing the latch at the bottom of the panel and lifting the door upwards. The door is fitted with gas struts to assist with keeping the door open, and an aluminum angle bracket on the right HS of the door will hold the internal electrical panel door in the open position for service.

The chiller is networked to the Danfoss VIP display so the operation can be monitored on the VIP screen.

The old chiller is now a backup chiller, and is manually valved out of circuit.

To restart the back up chiller the glycol hand valves need to be opened and the electrical selector switch needs to be changed from the ammonia chiller to the back up chiller.

Glycol System operation

The production process uses a boiler to heat glycol to approximately 120 deg C. The hot glycol heats the product in the batch which sterilizes the batch. When the batch is ready to be cooled the production control system changes over the valves in the production room (upstairs) from heating to cooling and the glycol is pumped down to the plate heat exchanger located outside the boiler room.

When the cooling cycle begins the dry cooler pump is started and the dry cooler fans are enabled.

Cool water from the dry cooler is pumped from the dry cooler through the plate heat exchanger and back to the dry cooler. The condenser water pump will also start allowing the chiller to start if the glycol in the buffer tank is above the set point.

The hot glycol passes through the plate heat exchanger heating the water in the dry cooler water system and cooling the hot glycol. The dry cooler fans will start once the water in the dry cooler is above 25 deg C and are speed controlled so that 25 deg C water is maintained in the dry cooler exit pipe whenever possible.

The dry cooler is a Guntner brand heat exchanger with eight EC fans, plus a water misting system .

The EC fans are controlled by a 0 to 10v signal from the Guntner fan controller.

The fans operate with step less speed control between 1 and 900rpm and are controlled by an on board electronic fan controller. The fans speed up as the leaving water temperature increases. When the fan get to maximum speed the water sprays start up in four equal stages. The spray system will dump the water in the spray pipe work when the sprays are not in operation.

If the water temperature is above 27 deg C the water mist system will spray water into the air around the dry cooler and the fans will draw the air into the coil blocks with the air. As the water droplets evaporate the air is cooled increasing the cooling capacity of the dry cooler.

When the glycol temperature in the production room drops to 30 deg C the production control system changes the cooling system valves over from the plate heat exchanger to the buffer tank.

The buffer tank will be normally maintained at 6 deg C by the chiller. When the 30 deg C glycol enters the buffer tank the tank temperature will rise which will call on the chiller via the chillers glycol pipe temp probe, and the chiller will start.

The chiller will operate on its own control system until the glycol is at or below 6 deg C and then it will cycle off.

When the product in the batch mixer reaches the set temperature the production glycol pump will shut down and the chiller cooling call will be cancelled.

Performance comparison

The existing chiller was an R22 air cooled design . As R22 is not a viable option in 2015 I have done a comparison to R134a, which is the most commonly used chiller refrigerant for this style of application.

The R134a air cooled chiller would generally have a condenser capable of a TD around the 10 to 15 k above the ambient temperature.

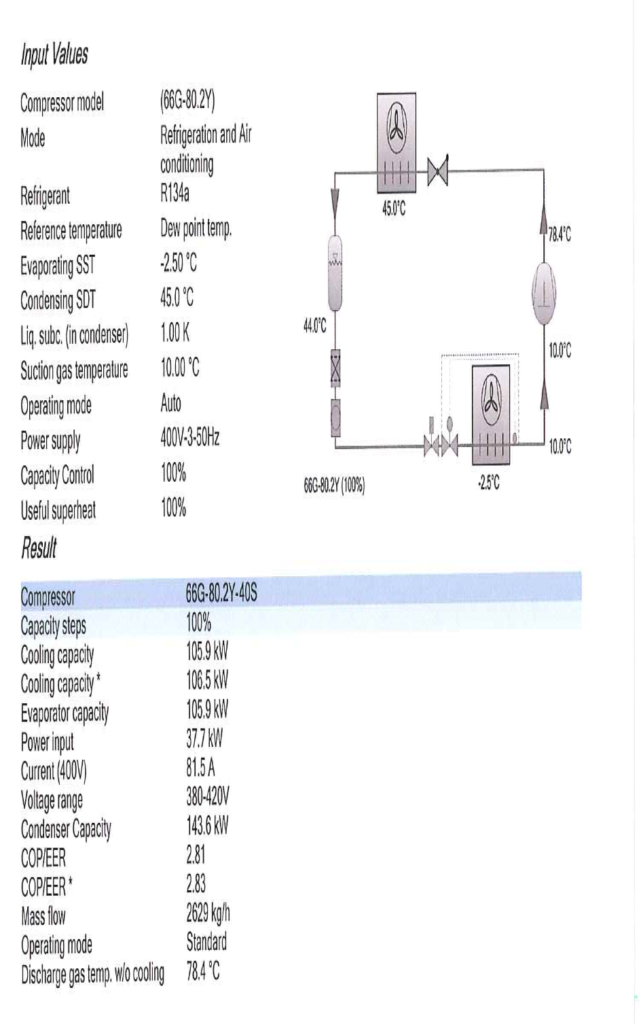

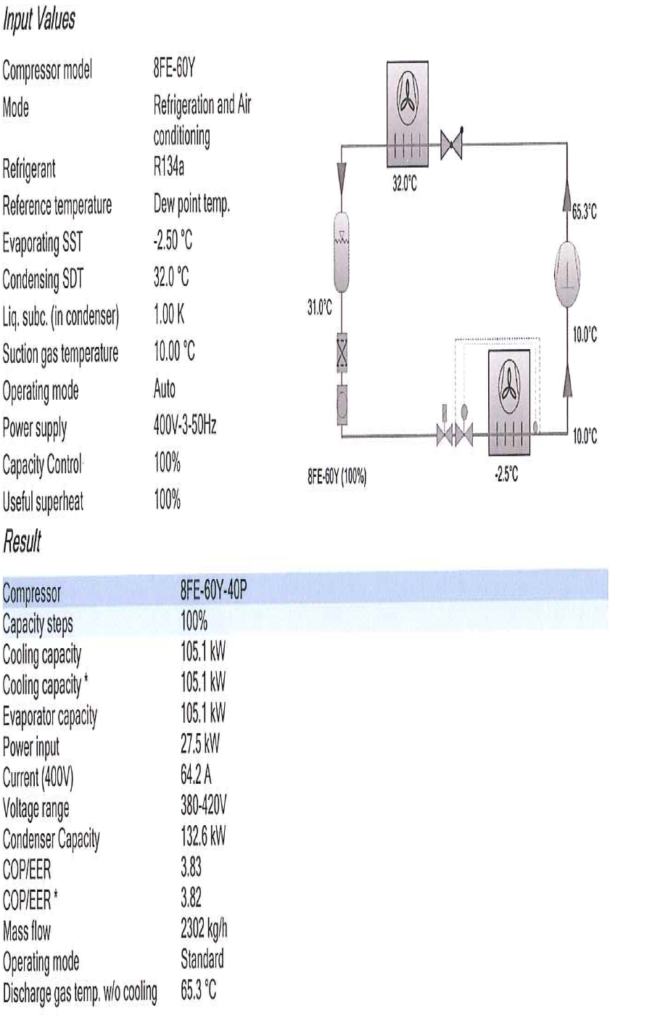

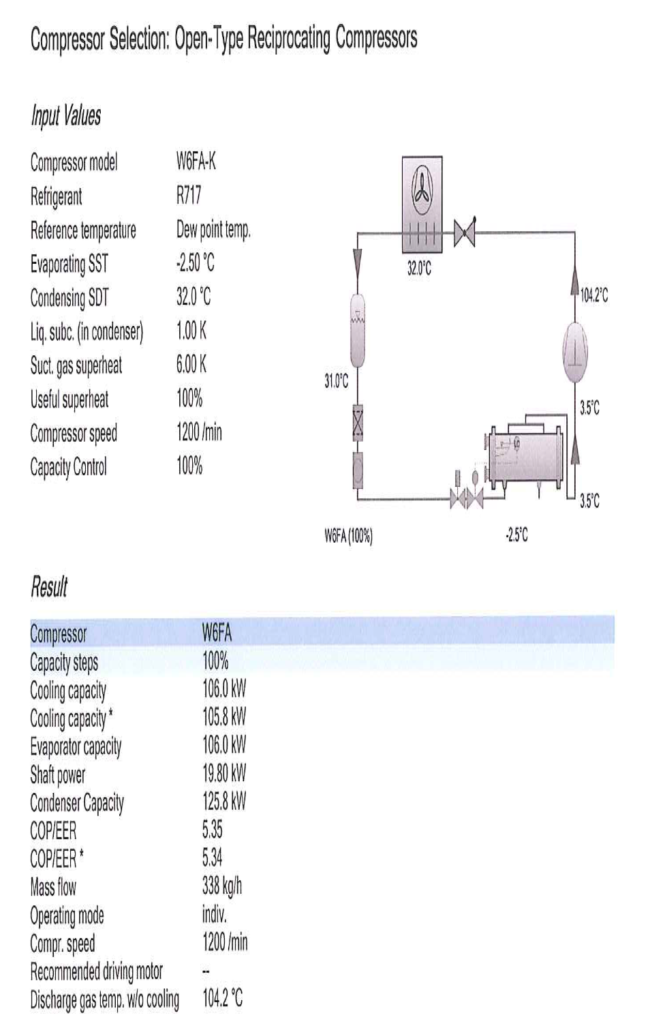

The performance data below shows a Bitzer compressor with R134a refrigerant in both air cooled (45 deg C condensing ) and water cooled ( 32 condensing ) with a piston type compressor.

It can be seen that the cooling capacity and COP is greatly reduced when the air cooled option is selected.

The above air cooled R134a chiller has a capacity of 105.9 kw Q & 37.7 kw of motor input power with a COP 2.81: 1 This option is nearest to the existing chiller that was replaced.

Note- this selection is for a tandem compressor set (two compressors bolted together as the drop in cooling capacity when an air cooled condensing temperature was inputted, would not allow a single R134a compressor to meet the capacity

The data above is for a water cooled R134a chiller . The cooling capacity is 105.1kw Q and the motor input power is 27.5 kw with a COP of 3.83

The data above is for the installed ammonia chiller . The cooling capacity is 106kw with the speed reduced by the VSD to 1200 RPM. The cooling capacity is 106kw Q and the motor input power is 19.8kw with a COP of 5.35 :1

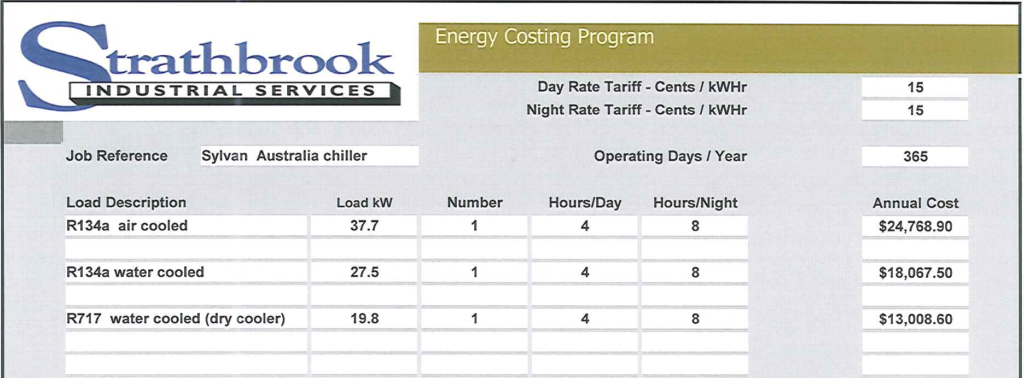

The table above shows the cost to run the compressor set over 12 months for each of the design options detailed above. The chiller normally starts in the afternoon and runs overnight so the product is ready for bagging the following morning . A 12 hour run time is the average production cycle.

I have assumed a power cost of 15 cents per kw hour .

It can be seen that the new ammonia chiller is 39% more cost effective than the water cooled R134a chiller and 90% more cost effective than the R134a air cooled design chiller.

This is not taking into consideration the additional power saving that is achieved by the ammonia heat recovery system which is heating water from 20deg C to 40 deg C during the production cycle.

Summary

The project appears to be a simple chiller change over , but the enervative use of the dry cooler in two operating modes and the inclusion of water sprays to boost the heat rejection capacity in hot ambient conditions coupled with the installation of a custom built critically charge ammonia direct expansion chiller has delivered a significant energy saving and reduced the production cycle time in the process.